Product Development and Design Services

Working in such diverse industries has provided 2think with a unique perspective in creating design solutions for a vast array of problems. It is this experience that lies at the very heart of value in 2think’s service offerings.

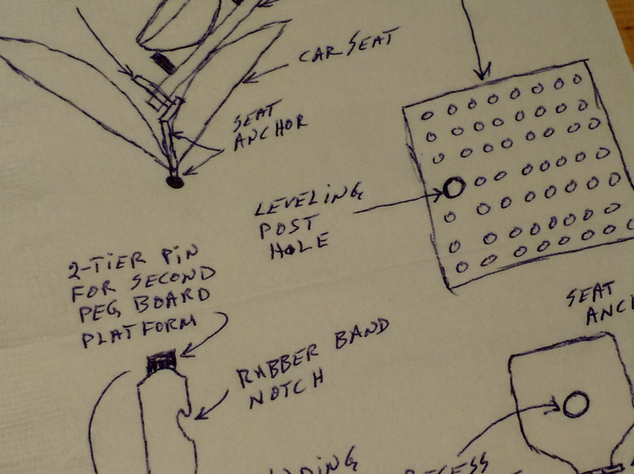

DEFINING THE "NAKED IDEA"

Services would include finding out, in much more detail, what the client had in mind as well as to search the market for any products remotely equivalent to their idea.

IDEA FINE TUNING

Here, the client will undoubtedly have a clear picture of how their idea should “operationally” function, but not sure how to “mechanically” execute it. We will propose alternative design ideas at this point, in order to maximize manufacturing effectiveness and minimize product price point.

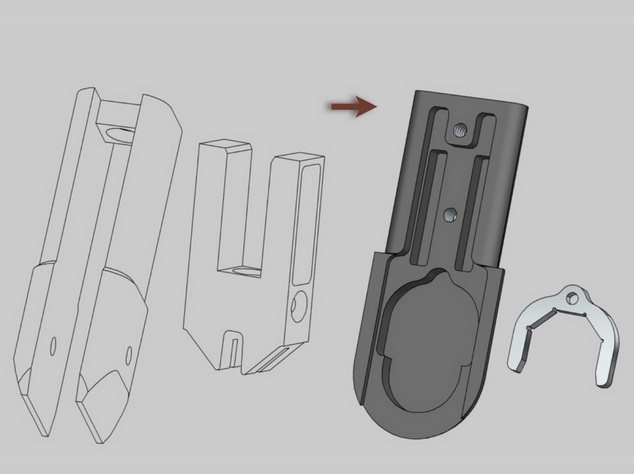

DESIGN DRAWINGS

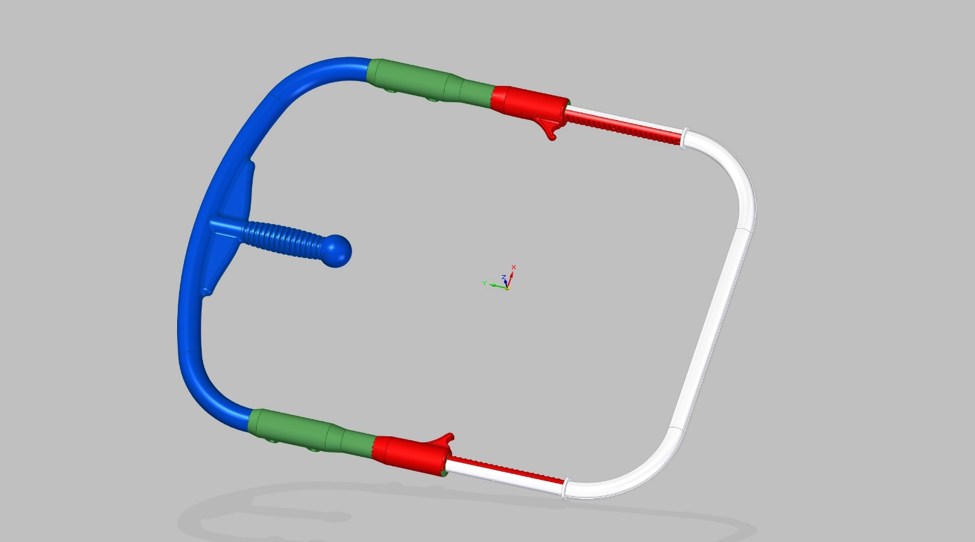

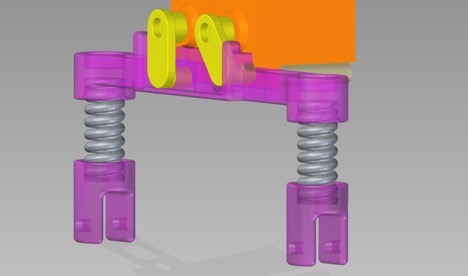

2think offers all the CAD (Computer Aided Design) services you need to effectively communicate your design ideas for presentation, collaboration and/or manufacturing. We are capable of importing/exporting the following mainstream CAD formats:

- .STL (3D Printing)

- .PAR (Native Solid Edge)

- .STEP

- .IGES

- .X_T

- .SAT

- .DXF (2D)

- .DWG (2D)

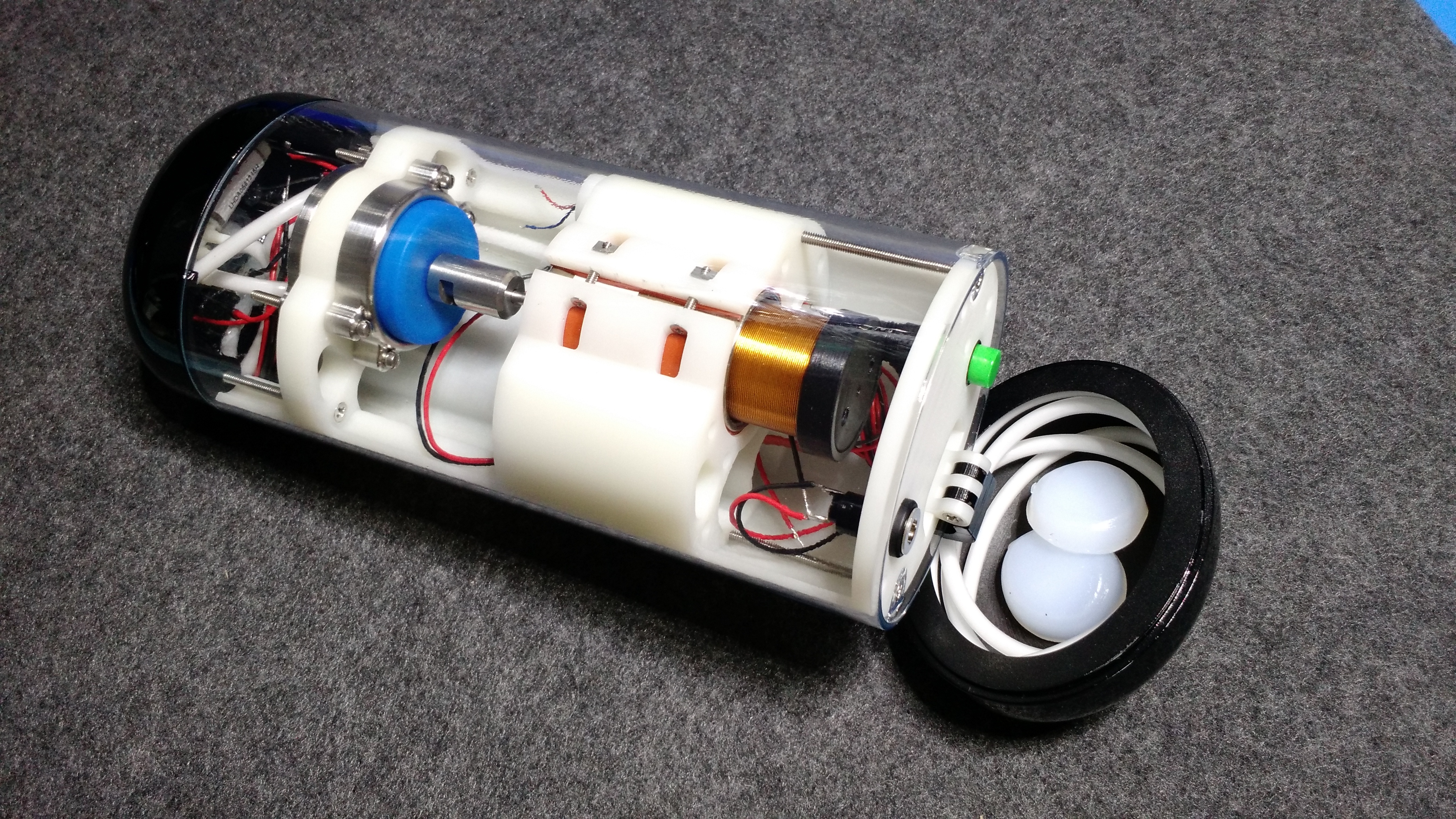

PROTOTYPE CONSTRUCTION

We have several resources at our disposal to aid in all aspects of physical prototype construction. These resources, whether it be in-house, domestic or foreign capabilities, or any combination thereof, include, but are not limited to the following:

- 3, 4 & 5 axis machining

- 3D additive manufacturing (3D printing) using several plastic and metal materials

- Cemented carbide

- Aluminum extruding

- Metal Stamping

- Water jet cutting

- Laser cutting and etching

- Plastic injection molding

- Compression, Rotation, Blow, Vacuum, etc. molding

- Aluminum anodization

- Bead blast finishing

- Vibratory tumble metal finishing

- Aluminum and Steel Forging

- Spray paint finishing

- Full Woodworking shop

- Other processes

INTELLECTUAL PROPERTY PROTECTION

2think knows the basics of Intellectual Property (IP) protection and can help you navigate through this extremely important facet of "idea protection". Although IP is NOT a “functional” requirement for any product, it is, however, highly recommend if a client plans to market their idea. 2think maintains a relationship with one of the most successful IP law firms in the business to further assist you in obtaining an officially "issued" US patent from the USPTO (United States Patent and Trademark Office) as well as obtaining foreign patents from other countries throughout the world, if a client so chooses.

MASS PRODUCTION IMPORT

If a client wishes to be their own Original Equipment Manufacturer (OEM), 2think maintains several offshore factory relationships, enabling it to ease the burden of final destination import logistics for its clients.

REVERSE ENGINEERING

If a client has one or more mechanical parts they wish to have re-engineered into 2D/3D drawings, 2think has the appropriate technology to accomplish this task with precision and insight.

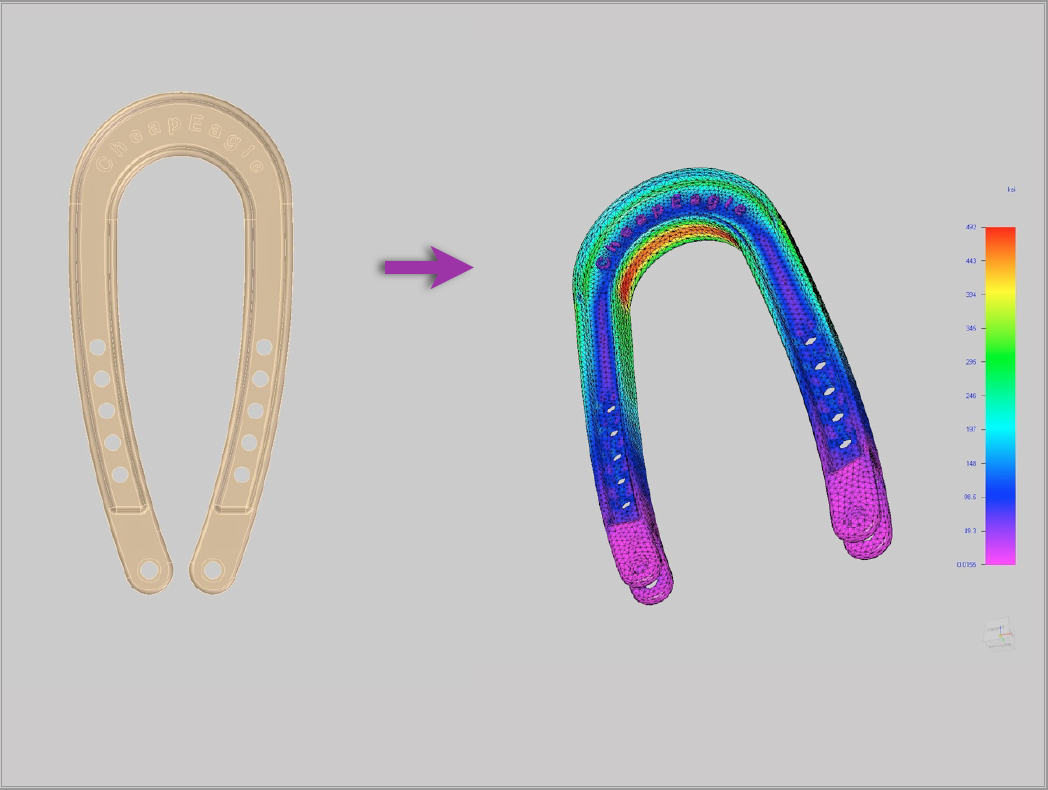

FINITE ELEMENT ANALYSIS (FEA)

2think makes use of FEA techniques to better visualize structural stresses within a part thereby assisting with the elimination of part weakness, resulting in increased functional efficiency and safety of the part. We retain the ability to perform rudimentary FEA analysis on single mechanical parts in one axis.

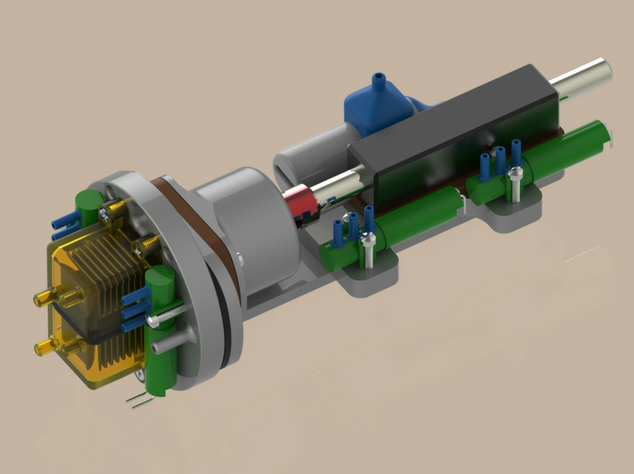

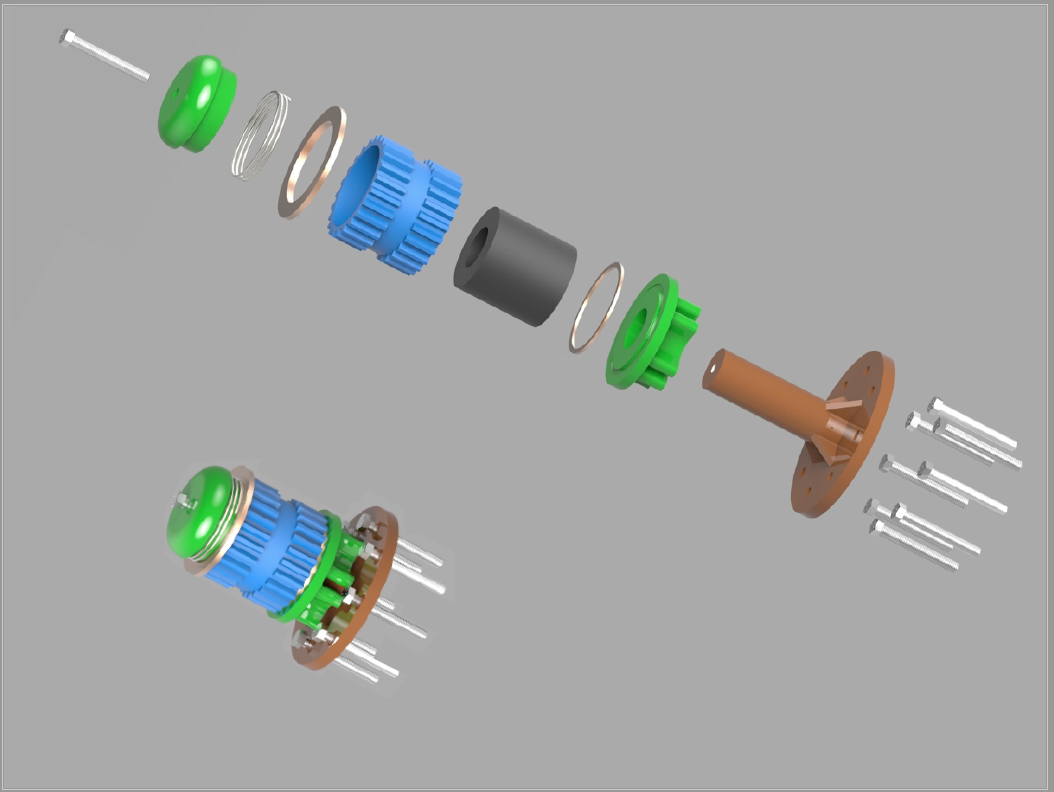

3D PRODUCT ANIMATION AND RENDERING

2think employs cutting edge rendering technology to illustrate inter-part movement relationships as well as producing photorealistic quality renderings of your finished product idea, worthy of any venture capital presentation and marketing effort.

The services which 2think has outlines above are actually listed in logical product development order. At each service stage, the following service builds upon the accomplishments of the prior service. There is one anomaly, however, to this straightforward sequence of events. This anomaly is when you reach the prototyping stage: once there, a client may stay in this stage for quite some time due to constant refinements required after each successive test use of the product. Once satisfied, the client finally emerges from this prototyping loop and continues with the logical progression of development.

A product’s full development cycle is 110% dependent upon its design complexity. Therefore, no one can give a precise answer to this question, but rather, a very educated approximation based upon the development company’s experience.

Most of the time, people cannot get their product into these retailers directly, although there have been exceptions to that rule. Quite often, people are required to go through a third party supplier to these Big Box retail chains to even be considered by the large retailers. Usually this entails people presenting the supplier with a VERY compelling “sales pitch”. If the supplier agrees that your product is a good fit for any of the retail chains, then they will make that case to them on your behalf. From there, it’s up to the retail chain to make the final decision on acceptance.

We’d Like To Meet You

No matter what stage of the development process, 2Think is here to take garage developers to corporations where they want to go with their product. Please take a moment to drop us a line so that we may discuss your design requirements.