CAD Drafting and Prototype Design Services

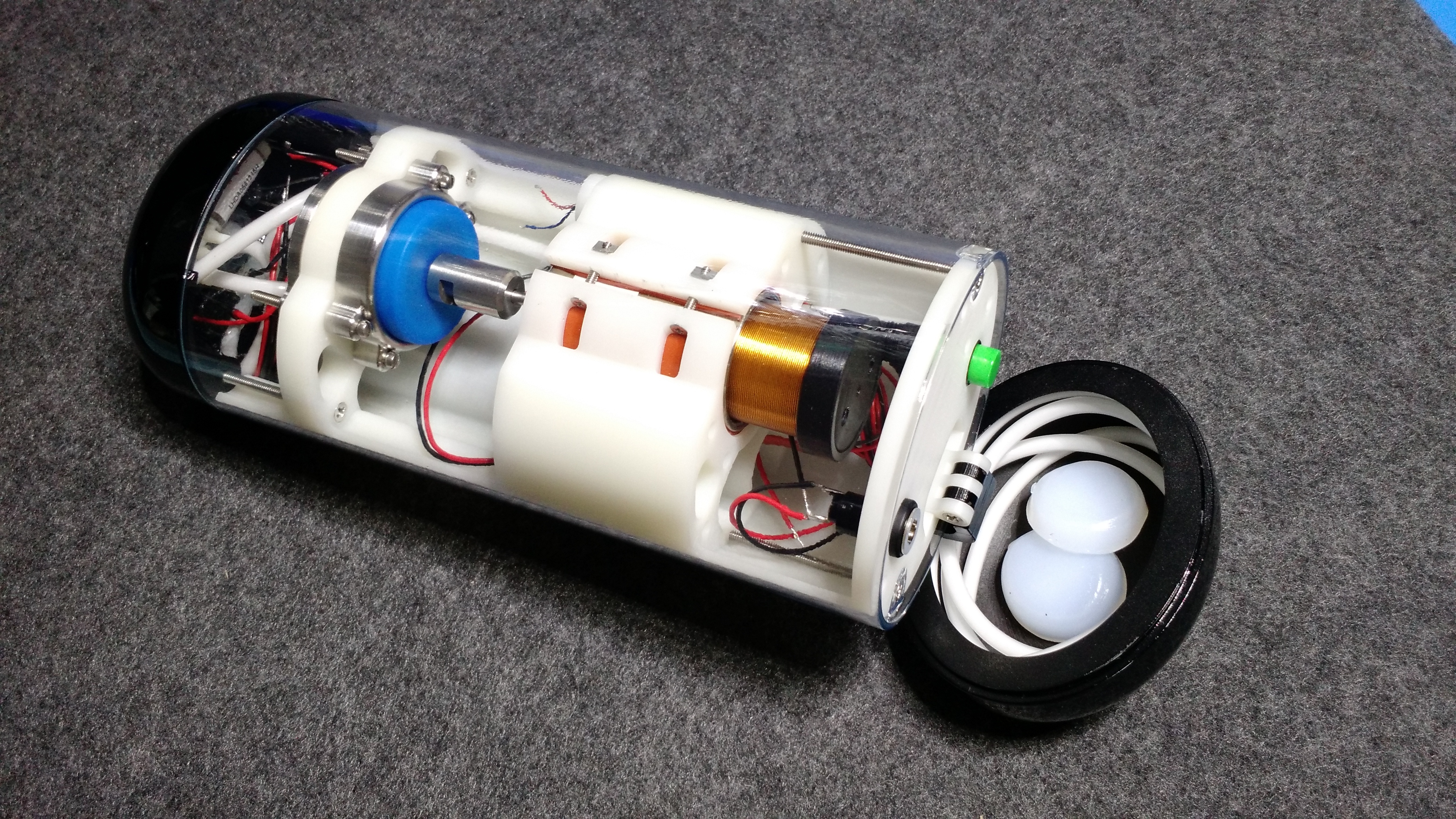

As a separate service from the full cycle of Product Development, 2think will construct one or more prototypes in order for the client to realize their ideas in functioning physical form.

We have several resources at our disposal to aid in all aspects of physical prototype construction. These resources, whether it be in-house, domestic or foreign capabilities, or any combination thereof, include, but are not limited to the following:

• 3, 4 & 5 axis machining

• 3D additive manufacturing (3D printing) using several plastic and metal materials

• Cemented carbide

• Aluminum extruding

• Metal Stamping

• Water jet cutting

• Laser cutting and etching

• Plastic injection molding

• Compression, Rotation, Blow, Vacuum, etc. molding

• Aluminum anodization

• Bead blast finishing

• Vibratory tumble metal finishing

• Aluminum and Steel Forging

• Spray paint finishing

• Full Woodworking shop

• Other processes

Absolutely. With the many materials available to use (predominantly metals and plastics), most of these can take on a beautiful surface finishes which can almost exactly mimic product parts. Finishing techniques such as Aluminum anodizing, bead blasting, media tumbling, spray painting, etc. can be employed to make your prototype part and assemblies look like a functional part or product.

Yes it can. Depending upon how rigorous the testing will be, we will suggest prototype construction methods, materials and assembly techniques which best fit your end-use testing application.

Building a prototype of an idea will always cost more than any production part 99.999% of the time. This is because prototyping produces very low volumes of parts and assemblies. All of the methods employed in constructing prototypes are generally setup on a case-by-case basis and therefore are more costly than setting up a manufacturing method one time and running thousands of parts using that one method. Therefore, each prototype must be dealt with like a “one off” build which, by its very nature, is much more time consuming and thereby more costly. Concerning any specific cost itself, that will be entirely dependent upon the complexity of what is required to be prototyped.

That answer is highly dependent upon the complexity of the part or assembly. In a relatively complex design, quite often there are several prototypes made to even demonstrate and test intermediate design steps of a single part or assembly or to test a very specific function and/or fit, more so than prototyping the overall part or assembly itself. However, for average to below average part or assembly complexity, one should expect to build around four prototypes, plus or minus, maybe, two.

We’d Like To Meet You

No matter what stage of the development process, 2Think is here to take garage developers to corporations where they want to go with their product. Please take a moment to drop us a line so that we may discuss your design requirements.